Optimise Production & Operations

Transform Manufacturing into a Self-Optimising Engine

Self-Optimising Manufacturing That Predicts and Prevents Problems

Production and Operations converts raw materials into finished products efficiently and safely. This capability manages manufacturing processes, quality control, maintenance, and resource optimisation. Operational excellence requires perfect balance of cost, quality, speed, and safety.

AI transforms production from reactive firefighting into predictive optimisation that maximises uptime, quality, and efficiency.

These transformative scenarios demonstrate how digibus.ai guides you to transform manufacturing through predictive maintenance, intelligent quality control, and autonomous optimisation—enabling you to minimise downtime while maximising quality accuracy.

Ready to Achieve Manufacturing Excellence Through AI?

Imagine operations that self-optimise, predict problems before they happen, and deliver consistent quality at peak efficiency. That's not the future—that's what digibus.ai delivers today.

Operational Excellence Delivered?

Reduction in Downtime: Predictive maintenance that prevents failures

Quality Accuracy: AI vision that catches what human eyes miss

Cost Savings: Smart optimisation across all operations

Your Manufacturing Advantage:

Autonomous systems that run themselves

Predictive insights that prevent costly disruptions

Quality control that approaches perfection

Energy optimisation that cuts costs and emissions

Turn your Plant into a Performance Powerhouse

AI-Powered Predictive Maintenance

Intelligent equipment monitoring and failure prediction to optimise maintenance schedules and maximise asset uptime through continuous analysis of equipment health using IoT sensors and machine learning algorithms.

CHALLENGE WITHOUT AI

Traditional maintenance approaches rely on fixed schedules or reactive responses to equipment failures, resulting in unexpected breakdowns that cause costly unplanned downtime, emergency repairs, and production disruptions.

AI SOLUTION OPPORTUNITY

AI analyses real-time sensor data including vibration, temperature, pressure, and performance metrics to identify patterns indicating potential equipment failures whilst machine learning models process historical maintenance data.

IMPACTED CAPABILITIES

Asset Management and Maintenance, Production Planning and Scheduling, Quality Assurance and Control, Resource Optimisation and Allocation, Risk Management and Compliance capabilities are enhanced through predictive insights.

TANGIBLE BUSINESS BENEFITS

Downtime reduction: Reduction in unplanned downtime, increase in asset productivity, and lower maintenance costs whilst extended equipment lifespan improves overall operational efficiency.

Cost optimisation: Improved spare parts inventory management, enhanced safety through proactive risk identification, and reduced emergency repair expenses through preventive maintenance strategies.

ROI achievement: ROI within months through decreased downtime costs and optimised maintenance spending whilst improved reliability enables better production planning and resource allocation.

AI-Driven Quality Control and Inspection

Automated real-time quality monitoring and defect detection using computer vision and machine learning for consistent product excellence with continuous inspection at production speed.

CHALLENGE WITHOUT AI

Manual quality inspection is slow, inconsistent, and prone to human error whilst visual defects and subtle quality issues often go undetected until products reach customers.

AI SOLUTION OPPORTUNITY

Computer vision systems equipped with AI algorithms continuously monitor production lines, analysing images and sensor data to detect quality issues in real-time whilst learning from historical patterns.

IMPACTED CAPABILITIES

Quality Assurance and Control, Production Process Management, Product Lifecycle Management, Customer Satisfaction and Retention, Regulatory Compliance and Standards capabilities benefit from automated quality monitoring.

TANGIBLE BUSINESS BENEFITS

Quality improvement: Defect detection accuracy, reduction in inspection costs, and decrease in scrap and rework rates whilst consistent product quality reduces customer complaints and returns.

Efficiency gains: Faster time-to-market for new products, improved regulatory compliance, and enhanced brand reputation through superior quality management and consistent excellence.

Performance enhancement: Improvement in first-pass yield and reduction in warranty claims whilst automated quality systems enable better resource allocation and strategic planning.

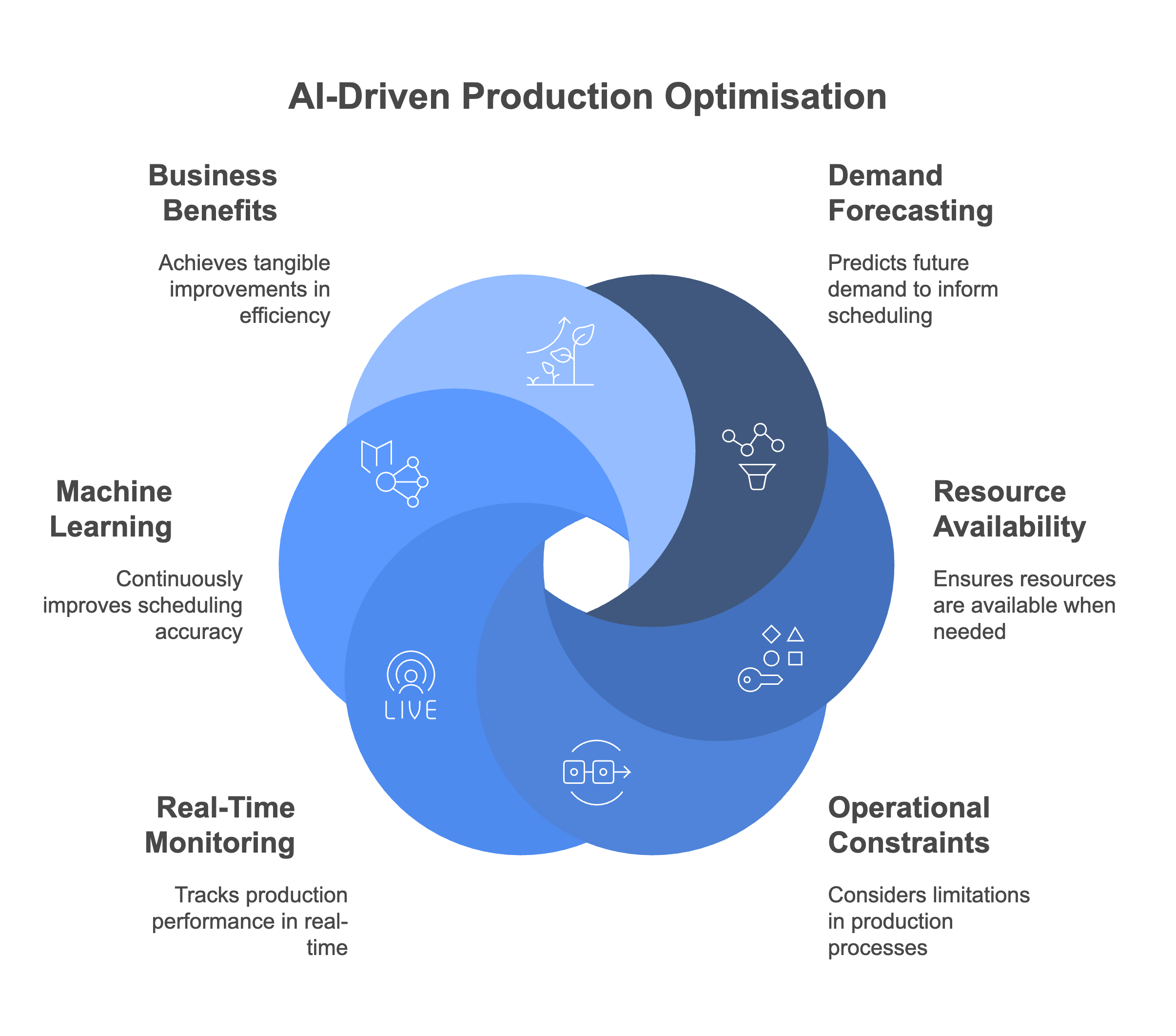

Intelligent Production Scheduling and Planning

AI-optimised production planning that dynamically adjusts schedules based on demand forecasts, resource availability, and operational constraints whilst continuously adapting to real-time conditions.

CHALLENGE WITHOUT AI

Traditional production scheduling relies on static plans that cannot adapt quickly to changing demand, supply disruptions, or equipment issues whilst manual processes are time-consuming and often suboptimal.

AI SOLUTION OPPORTUNITY

AI algorithms analyse demand forecasts, inventory levels, equipment capacity, and resource availability to generate optimal production schedules whilst machine learning models continuously improve scheduling accuracy.

IMPACTED CAPABILITIES

Production Planning and Scheduling, Demand Forecasting and Management, Resource Optimisation and Allocation, Supply Chain Coordination, Customer Order Management capabilities are enhanced through intelligent scheduling.

TANGIBLE BUSINESS BENEFITS

Delivery performance: Improvement in on-time delivery performance, increase in production throughput, and reduction in scheduling and planning time whilst optimised resource utilisation improves efficiency.

Operational efficiency: Reduced work-in-process inventory, improved customer satisfaction through reliable delivery, and enhanced ability to respond to urgent orders through flexible scheduling.

Equipment effectiveness: Improvement in overall equipment effectiveness and reduction in production cycle times whilst better planning enables more strategic resource allocation and capacity management.

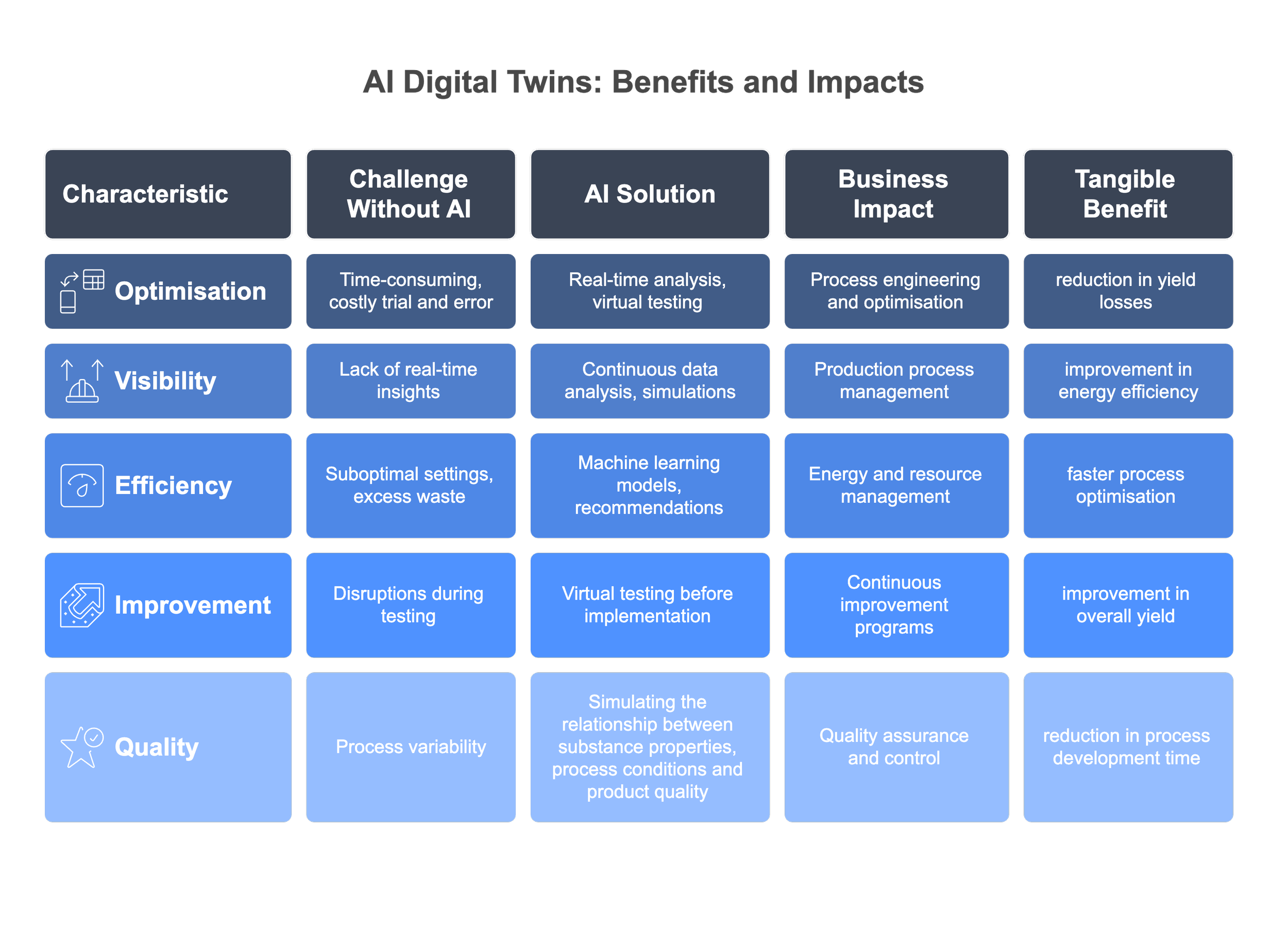

Process Optimisation Through AI-Powered Digital Twins

Virtual production environment modelling that enables real-time process optimisation and scenario testing for maximum efficiency whilst creating virtual replicas of production processes.

CHALLENGE WITHOUT AI

Complex manufacturing processes involve numerous variables that interact unpredictably whilst process engineers lack real-time visibility into optimal operating conditions and cannot quickly test improvements.

AI SOLUTION OPPORTUNITY

AI-powered digital twins create virtual replicas of production processes that continuously analyse real-time operational data to identify optimisation opportunities whilst machine learning algorithms model relationships automatically.

IMPACTED CAPABILITIES

Process Engineering and Optimisation, Production Process Management, Quality Assurance and Control, Energy and Resource Management, Continuous Improvement Programs capabilities are enhanced through virtual modelling.

TANGIBLE BUSINESS BENEFITS

Process efficiency: Reduction in process variability and reduction in yield losses and scrap rates whilst improvement in energy efficiency and faster process optimisation cycles.

Resource optimisation: Reduced raw material consumption and enhanced process understanding whilst improvement in overall yield and reduction in process development time through virtual testing.

Development acceleration: Virtual testing of process changes before implementation reduces risk and accelerates improvement initiatives whilst maintaining operational stability and quality standards.

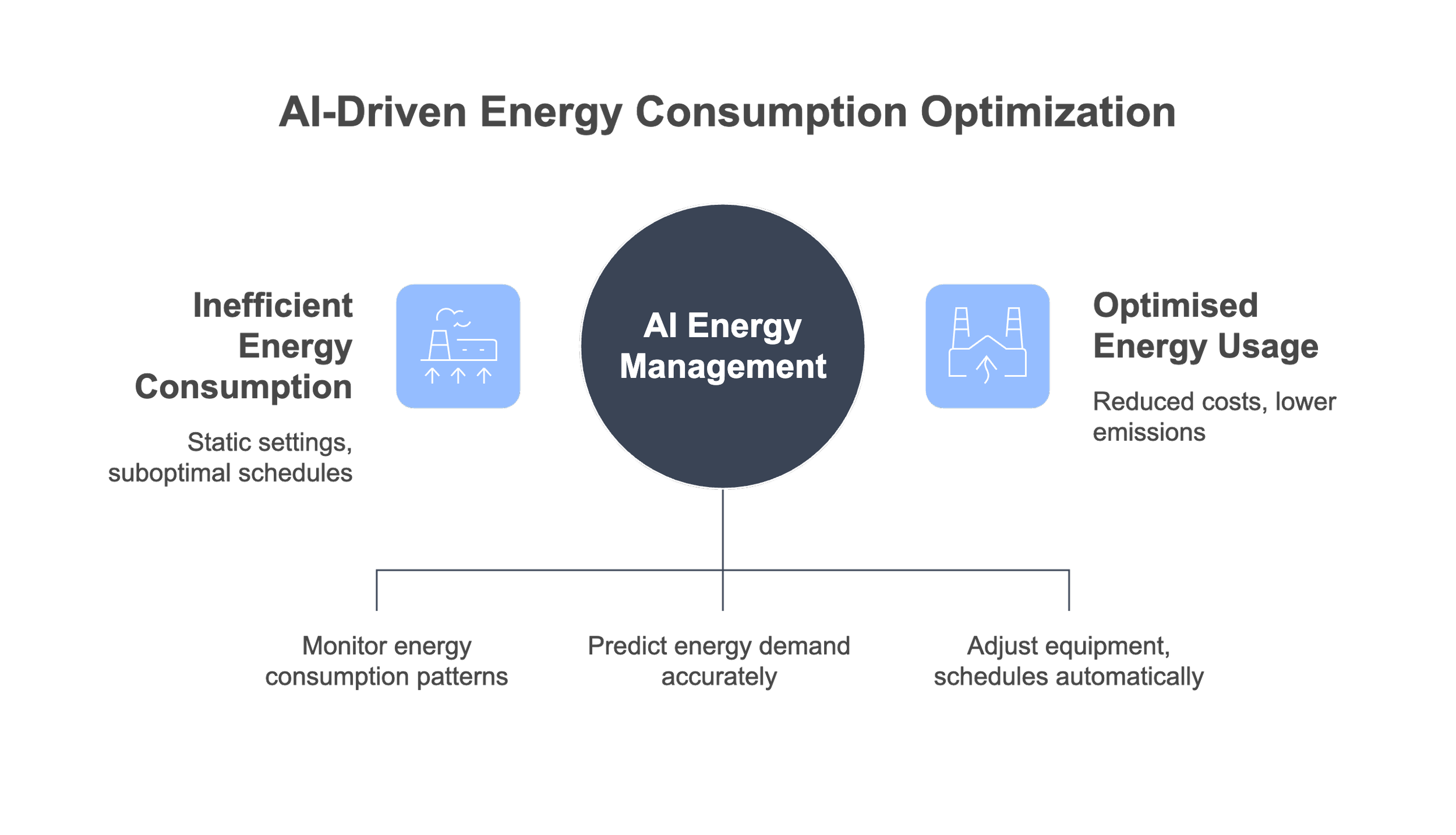

AI-Enhanced Energy and Resource Optimisation

Intelligent energy and resource management that continuously optimises consumption patterns to reduce costs and environmental impact whilst automatically adjusting equipment settings and production schedules.

CHALLENGE WITHOUT AI

Energy consumption in manufacturing operations is often inefficient due to static equipment settings whilst manual energy management cannot respond quickly to changing conditions.

AI SOLUTION OPPORTUNITY

AI algorithms continuously monitor energy consumption patterns, equipment performance, and production requirements to optimise energy usage in real-time whilst predicting demand and adjusting operations automatically.

IMPACTED CAPABILITIES

Energy and Utilities Management, Production Planning and Scheduling, Environmental Sustainability Management, Cost Management and Control, Resource Optimisation and Allocation capabilities are enhanced through intelligent optimisation.

TANGIBLE BUSINESS BENEFITS

Cost reduction: Reduction in energy consumption, decrease in utility costs, and significant improvements in carbon footprint reduction whilst maintaining or improving production performance.

Sustainability improvement: Improved sustainability metrics, reduced environmental compliance costs, and enhanced corporate reputation through responsible resource management and operational excellence.

Financial returns: Payback periods through energy cost savings whilst qualification for green financing and incentives provides additional financial benefits and competitive advantages.

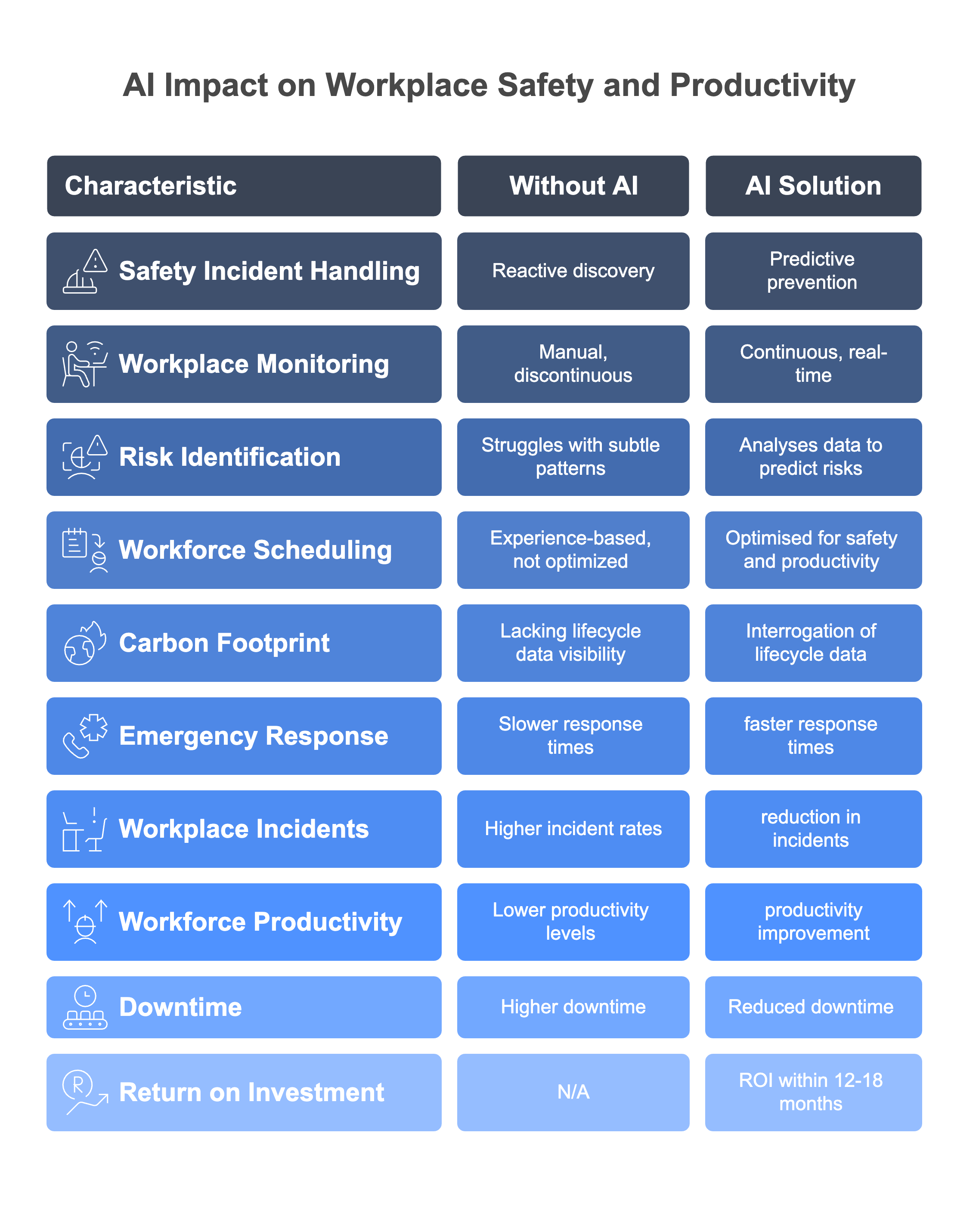

AI-Powered Safety and Workforce Optimisation

Intelligent safety monitoring and workforce optimisation that enhances worker protection whilst maximising human productivity and operational efficiency through continuous monitoring and predictive analytics.

CHALLENGE WITHOUT AI

Workplace safety incidents are often reactive discoveries whilst manual safety oversight cannot provide continuous coverage across all work areas and traditional approaches struggle with subtle risk patterns.

AI SOLUTION OPPORTUNITY

AI systems use computer vision and sensor networks to continuously monitor workplace conditions whilst machine learning algorithms analyse historical incident data to predict and prevent safety risks.

IMPACTED CAPABILITIES

Health, Safety, and Environmental Management, Workforce Planning and Management, Training and Development Programs, Risk Management and Compliance, Human Resources Management capabilities are enhanced through intelligent monitoring.

TANGIBLE BUSINESS BENEFITS

Safety improvement: Reduction in workplace incidents, faster emergency response times, and improvement in workforce productivity whilst reducing insurance costs and improving regulatory compliance.

Operational efficiency: Enhanced employee satisfaction and retention, reduced training costs through personalised programs, and better utilisation of workforce skills and capabilities through optimisation.

Performance enhancement: ROI through reduced incident costs and improved productivity whilst continuous monitoring provides real-time feedback and enables proactive safety management strategies.